Sewage & Storm Water Bypass Pumping

What is Sewage Overpumping?

Over pumping or bypass pumping is typically required when an existing sewage or storm water network needs to be upgraded. As the existing systems are live and it is often not possible to simply turn them off as the population keep producing effluent, a temporary overpumping alternative must be found. It is common in Cities such as Dubai and Abu Dhabi where the population and strain on the sewage and storm water network is ever growing, for pipes, pumping stations and manholes to be upgraded. During the maintenance works surface pumps will be used to pump water or effluent from a manhole located upstream of where the upgrade is required, pump it along the ground through HDPE pipework, and back into another manhole located downstream of the works. This will divert the flow allowing the works to be completed safely.

To provide a dry working condition, mechanical or inflatable packers and plugs can be inserted downstream from the temporary overpumping system and upstream of the proposed works to stop flow of fluid towards the worksite. To install a packer or plug, first the incoming flow should be controlled or reduced and undertaken in co-ordination with local authorities such as DEWA and RTA in Dubai, and ADSSC and ADWEA in Abu Dhabi. Installation of packers and plugs requires specialist technicians to enter confined spaces in manholes and potentially hazardous working condition

It is common for flows to vary throughout the day depending on the load on the sewage or stormwater system. When designing a temporary over pumping system it is good practice to undertake inspections prior to commencing the works to estimate the peak and low flows. Particularly when pumping sewage it is very important to ensure that sufficient standby pumping capacity is provided, and therefore it is common for systems to have 100% standby capacity. During maintenance and in the event of mechanical failure or rags and debris blocking up suction lines on pumps, this is where full time supervision, alarms and standby pumps allows for safe and confident operation

Once the repairs or upgrade of the sewage and storm water system is complete, the inflatable packers or plugs can be removed, and then the temporary overpumping system can be demobilized.

The benefits of HDPE over layflat hoses include a reduction in friction loss leading to reduced fuel consumption and pump sizes, higher quality finish, aesthetically pleasing, resistant to sunlight and salt water, and more robust and less prone to damage.

Electrofusion is a little different to fusion butt welding as it uses factory made polyethylene (PE) electrofusion fittings to melt and join pipes together. Inside each electrofusion fitting or coupling there is a resistance wire heating coil mechanism. An electrofusion control unit when temporarily connected to the fitting via two cables passes a controlled electrical voltage to the heating coils, resulting in the coils heating up and melting the fitting and pipe surfaces together. As the pipes heat up they will expand and fill up the gap between the pipe and fitting creating a strong joint. The majority of electrofusion fittings come with a bar code which is scanned into the electrofusion machine by the operator to determine the temperature and time for heating. As with fusion butt welding, it is important to keep the pipes clean, free of any oil, grease and dust, remove oxidized surface with a scraper prior to joining, heating for sufficient time and temperature, and providing sufficient cooling down time to achieve a strong weld.

Key benefits of electrofusion over butt welding is that the equipment is much smaller and can be carried out in confined spaces. WJ have used electrofusion for emergency repairs to damaged or burst pipes, for making intricate joints in tight locations, and for joining vertical HDPE pipes in stairwells.

Why use WJ?

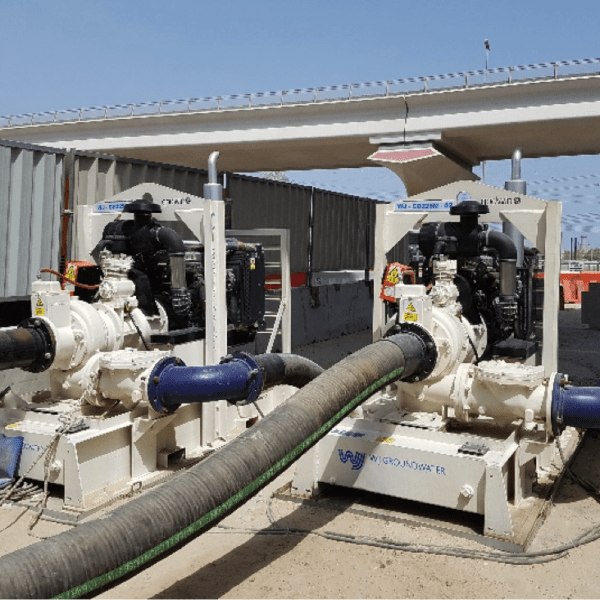

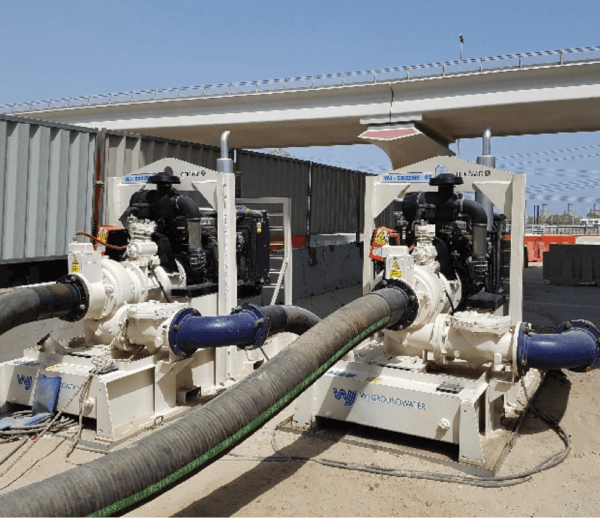

WJ can carry out complete temporary installation and operation providing total solution. WJ maintains a large fleet of surface mounted high flow diesel pumps with large solids handling capacity of 30mm to 120mm. When surface mount is not an option, we can also achieve similar pumping capacity using our electric submersible drainage and sewage pumps. Many of the pumps that WJ operate also have large rag handling capacity to bring you the best in overpumping technology.

When designing and proposing an overpumping system WJ will work closely with Authorities, Clients and Main Contractors, with a site visit, to estimate or further understand the following:

- Minimum and maximum flow and associated times

- Type of pumped medium (fresh water, salt water, raw sewage, treated effluent etc.)

- Duration of works

- Site constraints and geometry

- Discharge and suction line routes

- Diameter of manhole and pipelines (internal and opening size)

- Required drawdown within manhole (key to calculate NPSH)

- Plugging or packer requirements

- Permits and NOCs required

- Supervision and monitoring requirements

WJ aim to design, engineer, install and commission the optimal over pumping solution for effective bypass. Our Engineers can assist in calculating the peak flow, temporary piping connections, required pipe length and diameter, drawdown required to avoid flooding upstream manholes, discharge head losses and solid handling parameters.

In short, we will choose the best and cost-effective pumping system that is ideal for your site conditions.

Featured Sewage & Storm Water Bypass Pumping Projects

The Garden Sewage Treatment Works

WJ undertook sewage over pumping works as part of maintenance works at The Gardens Sewage Treatment Works in Dubai. WJ were contracted by Hydrojet to divert incoming mains sewage from the works inlet to the neighbouring aeration tanks whilst they carried out maintenance works at the pumping station for Nakheel. WJ installed a high performance

Stormwater Bypass, Nakheel Metro Station

Over pumping for the upgrade of existing Metro Station Description: The Nakheel Harbour and Tower (NHT) Station upgrade is a part of the Dubai Metro expansion works and it is located on Ibn Battuta Street. The Red Line Metro extension to Expo 2020 site shall intersect at NHT Station. WJ Groundwater Limited undertook the storm

Stormwater Bypass near Jumeirah

Over pumping from manhole for constructing additional downstream manhole Dubai Municiaplity continue to invest and build on their existing utility network in Dubai. As part of upgrades, WJ Middle East undertook the storm water by pass works from manhole to manhole at Jumeirah using our high capacity diesel centrifugal pumps. We installed our heavy-duty temporary HDPE