High Rise

For decades, high rise construction projects in Canada have brought with them a unique set of challenges related to dewatering. Now for the first time, there are new dewatering options available from WJ Groundwater Canada for developers and GC’s to consider.

WJ’s unique fixed cost contract options for high rise projects and extensive global experience makes achieving the, often significant, drawdown required on these projects, where up to 6 underground parking levels are required, straightforward.

Exceptional Performance

Based on our experience with over 2500 dewatering projects worldwide since 1982 and our specialization in dewatering the most challenging deep excavation, tunnel and LRT mega projects over the years, our engineers have developed high performance drilling equipment, pumping processes, well point systems, eductors and dewatering design services that offer an exceptional level of performance for dewatering high rise projects.

In addition, WJ’s 24 hour pump tests can be leveraged by our clients and their advisors to better understand the hydrological profile of any site and precisely size the dewatering system needed to achieve draw down goals. When this is combined with our in-depth understanding of local geology and high levels of dewatering system performance, along with our pro-bono engineering services, this makes WJ the perfect dewatering partner for developers and GC’s for the high rise business in Canada.

For example, leveraging WJ expertise can help our high rise clients avoid spending millions in temporary bath tubbing costs or more expensive caisson wall systems designed to resist hydrostatic pressures.

WJ’s 360 degree, water rotary flush drilling makes all the difference

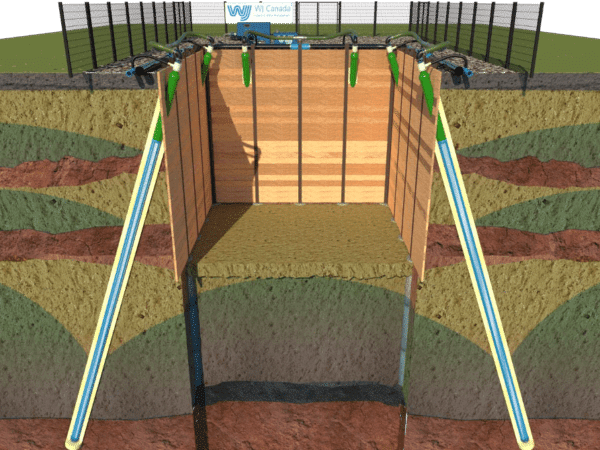

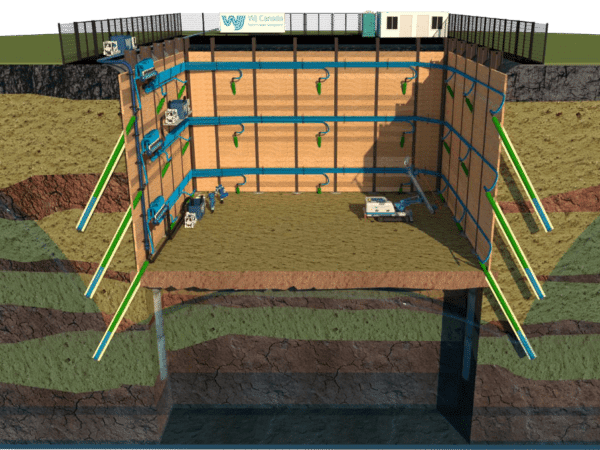

WJ use articulated and flexible drilling rigs, perfect for tight construction sites, which use water rotary flush methods which ‘pressure wash’ the bore prior to the installation of our etended screen eductors. This combination of our state of the art bespoke drilling rigs and well technology makes WJ the ideal choice for high rise projects where space and access is often at a premium.

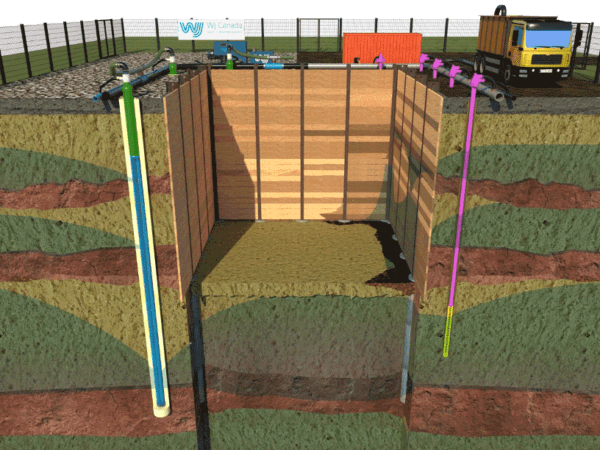

- Major Savings Over Traditional Perimeter Eductor Based Systems in High Rise Projects. WJ’s 360 degree drilling methods and well designs give WJ the flexibility to install our dewatering systems through lagging or shoring walls using a number of options including inclined well points, inclined eductors, as well as from the surface or bottom of the excavation. This flexibility is unique to WJ and this advanced technology can provide a cost effective dewatering alternative for your project compared to “traditional” 2” perimeter eductor systems (see Inclined wellpoint and eductor through Lagging illustrations below).

- TSS Free Water. In addition, the combination of WJ’s water flush drilling methods and WJ’s eductor and well point extended screening methods, results in nearly TSS free discharge water – and completely eliminates the need, space and cost of a sedimentation tank system.

- Improved Eductor Dewatering Performance. WJ’s extended screen design improves hydraulic connectivity through layered soils compared to vertical wells screened only at the bottom. Illustration shows blue extended well screen eductor vs purple short screen eductor.

Fixed-Cost Dewatering Option

Here at WJ Canada we’re confident in our capabilities. Our confidence allows us to offer a fixed price dewatering option for contracted clients.

Choose WJ and you’ll know where you stand from day one.

Find out more

Get in touch if if you’d like to find out more about our solutions for High Rise dewatering or our fixed cost dewatering.