On many projects, the owners and builders have to decide whether dewatering is possible based on hydrogeological and geotechnical reports. If they cannot dewater due to the difficult groundwater conditions it can result in dramatically escalating costs – potentially by millions of dollars – as it may be necessary to install temporary “bath tubs” around the excavation to waterproof the foundation, or implement expensive shoring solutions vs. the lower cost lagging.

For most situations being able to dewater vs. bath tubbing is a far, far lower cost option. For example bath tubbing could cost an additional $3M – $5m + for some High Rise Projects.

In many cases, the hydrogeological and geotechnical reports commissioned by the owner/developers early in the project may not be complete. Sometimes owners may look to cut corners and spend less than needed, or the uncertainty in the data requires the hydrogeologist to use a larger factor of safety in their calculations.

WJ’s Pump Tests Solution

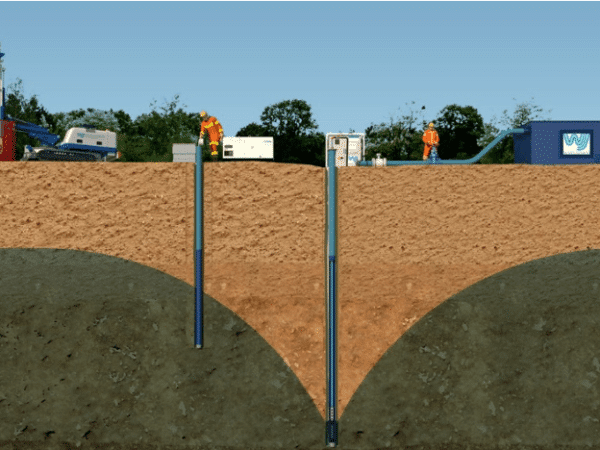

WJ have developed methods, drilling and pumping processes and equipment that create an extremely accurate 24 hour constant-rate pump test that, when combined with WJ’s engineering analysis, can produce the accurate data needed to:

- Determine whether dewatering is feasible or required

- Design, size and cost the dewatering system needed to achieve the necessary draw down to dewater the project

- Provide assistance value-engineering during shoring system selection

- Determine whether water treatment will be needed and the potential cost

- Determine if water treatment for storm sewer discharge will provide a cost-effective solution for high volume projects, or where sanitary sewer capacity restrictions mandate discharge to the storm sewer

Our experience reduces your cost

Over the last 30 years WJ has developed its own processes and methods to produce pump tests that stress the aquifers on a project/property in a way that reveals the groundwater conditions in relation to determining the exact dewatering requirements.

To be able to produce these highly accurate pump tests on a timely basis for our clients we have invested in highly skilled and trained staff, and a huge array of equipment that includes pump test control cabins with variable speed drive pump controls, electromagnetic flow meters, discharge tanks, data loggers, geotechnical instrumentation and sensors. We’ve also created specialized drilling capabilities and techniques that allow a superior connection to the aquifers.

The result is a reduction in the uncertainty of the ground conditions improving the chance of project success and opening up possibilities to reducing overall project costs.